-

Προϊόντα

-

Όργανα εργαστηρίου

Άλλα όργανα

- Εργαστηριακοί µετρητές και αισθητήρια

- Χηµικές ουσίες, αντιδραστήρια και πρότυπα

-

Online Analysers

Αναλυτές αµµωνιακών Αναλυτές χλωρίου

- CL17sc

- CL10 sc Αµπεροµετρικό

- 9184 sc Αµπεροµετρικό

- Χρωµατοµετρικός αναλυτής χλωρίου CL17sc εξαιρετικά χαµηλού εύρους µέτρησης

EZ Series Analysers- Σίδηρος

- Αργίλιο

- Μαγγάνιο

- Φωσφορικά

- Χλωριούχα

- Κυανιούχα

- Φθοριούχα

- Θειικά

- Θειώδη

- Αρσενικό

- Χρώµιο

- Χαλκός

- Νικέλιο

- Ψευδάργυρος

- Αµµωνιακά

- Ολικό άζωτο

- Ολικός φώσφορος

- Φαινόλη

- Πτητικά λιπαρά οξέα

- Αλκαλικότητα

- ATP

- Σκληρότητα

- Τοξικότητα

- Σύστηµα προρρύθµισης δείγµατος

- Βόριο

- Χρώµα

- Νιτρικά

- Νιτρώδη

- Διοξείδιο του πυριτίου

- Υπεροξείδιο του υδρογόνου

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

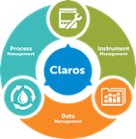

- Claros Water Intelligence System

-

Online αισθητήρια και ελεγκτές

Ψηφιακοί ελεγκτές (Μεταδότες) Ελεγκτές (αναλογικοί) Αισθητήρες Αµµωνιακών Αισθητήρας παρακολούθησης υδρόθειου

- Κιτ δοκιµών και δοκιµαστικές ταινίες

- Αυτοµατοποιηµένα συστήµατα εργαστηρίου

-

Μικροβιολογία

Όργανα Παρασκευασµένα µέσαΠαρελκόµενα και χηµικές ουσίες Σκεύη εργαστηρίου

-

Εξοπλισµός και προµήθειες εργαστηρίου

Βιβλία και υλικό αναφοράς Γενικά αναλώσιµα εργαστηρίουΓυάλινα σκεύη/Πλαστικά σκεύηΌργανα Συσκευή

- Δειγµατοληψία

- Ηλεκτροχηµεία

-

Όργανα εργαστηρίου

-

Λύσεις λογισμικού

-

Claros Water Intelligence System

Στοιχεία προϊόντος Process Management

- Παρέχει λύσεις για:

- Αφαίρεση BOD/COD

- Νιτροποίηση/Απονιτροποίηση

- Αφαίρεση φωσφόρου

- Διαχείριση ιλύος

Data Management- Παρέχει λύσεις για:

- Συλλογή

- Οπτικοποίηση και διαδικασίες ανάλυσης

- Δημιουργία αναφορών

- Ακρίβεια δεδομένων

Instrument Management- Παρέχει λύσεις για:

- Συντήρηση

- Αντιμετώπιση προβλημάτων

- Απομακρυσμένη πρόσβαση

- Σύγκριση εργαστηριακών και συνεχών μετρήσεων

Προκλήσεις για τη Βιομηχανία Κανονιστική συμμόρφωση Εξοικονόμηση κόστους Απομακρυσμένες λειτουργίες Διαχείριση δεδομένων Βελτιστοποίηση διεργασιών Συντήρηση εξοπλισμού

-

Claros Water Intelligence System

- Βιομηχανίες

- ΥΠΟΣΤΗΡΙΞΗ

- ΝΕΑ & ΓΕΓΟΝΟΤΑ

- Hach

AnaShell walk-in Analytical Shelter Type AS4100, for up to three analysers plus sample preconditioning, with window

- Επισκόπηση

- Λεπτομέρειες

- Λήψεις

- Βίντεο

Αρ. προϊόντος:

AS4100

Τιμή μονάδας

Επικοινωνήστε μαζί μας

Safe housing with laboratory-like conditions

The insulated AnaShell analyser shelters, including the base plate, are made of glassfiber reinforced polyester (GRP) on a stainless steel frame. The self-supporting construction has a high mechanical strength and withstands even extreme weather conditions. Protection class IP54 (NEMA 3X) means dust-tight and water jet proof, ensuring your analysers are well protected. In conjunction with an air conditioning system, consistent ambient conditions can be achieved - ideal conditions for accurate results.

Professional Integration

We develop your AnaShell enclosure as a turnkey complete solution. Sample perconditioning and analysers are permanently mounted on chemical resistant High Pressure Laminate (HPL) plates with galvanized modular mounting profiles (MMP). The necessary connections are planned accordingly, all cables and hoses are clearly marked and easy to read. You will receive extensive documentation for your shelter, e.g. technical drawings for electrics, 2D floor plan and P&ID.

Safety is a top priority

AnaShell shelters intended for outdoor installation come with lightning protection. They feature two separate grounding systems: equipment (AC safety) and isolated shield grounding system. All non-energized parts of the equipment are bonded to the shelter equipment (AC safety) ground bus through dedicated bonding cables.

High quality door hinges are designed for the long service life of the shelter. The anti-panic bar ensures that the shelter's door can be opened from the inside in an emergency - even if the door is locked from the outside.

Small installation effort, fast commissioning

Each AnaShell enclosure is mounted incl. all analysers in our plant and tested before shipping. Four lifting and mounting brackets (90° rotatable) facilitate transport and installation on site. Unload, unpack, set up, connect - ready for the first sample.

Certification included

AnaShell enclosures have passed the necessary tests and are certified with CE Declaration of Conformity according to Machine Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery and EMC Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility.

Τι περιέχει το καλάθι

AnaShell analytical shelter type AS4100 in ordered configuration; process instrumentation and sample preconditioning pre-assembled and mounted ex works according to order

Προδιαγραφές

Heating system:

Optional, combinable:

- Thermostatically controlled electrical heating (2000 W)

- Thermostatically controlled air conditioning unit with heat pump (2500 W / 2800 W). The air conditioning unit is a wall mounted split version, so no outside ventilation air is blown into the cabinet.

- Thermostatically controlled air conditioning unit with heat pump (2500 W / 2800 W) for corrosive environments with corrosion-resistant coating on the outside heat exchanger unit. The air conditioning unit is a wall mounted split version, so no outside ventilation air is blown into the shelter.

- Thermostatically controlled electrical heating (2000 W)

- Thermostatically controlled air conditioning unit with heat pump (2500 W / 2800 W). The air conditioning unit is a wall mounted split version, so no outside ventilation air is blown into the cabinet.

- Thermostatically controlled air conditioning unit with heat pump (2500 W / 2800 W) for corrosive environments with corrosion-resistant coating on the outside heat exchanger unit. The air conditioning unit is a wall mounted split version, so no outside ventilation air is blown into the shelter.

Signal junction box:

Optional:

- One (1) combined local signal junction box for analog signals (4 - 20 mA, max. load 500 Ohm) and alarms (potential free contacts, max. 24 V DC). Max. 24 pairs (equals 48 terminals). Mounted on the outside wall of the shelter (shielded by pair).

- Two (2) local signal junction boxes. One box for analog signals (4 - 20 mA, max. load 500 Ohm). One box for alarms (potential free contacts, max. 24 V DC). Max. 12 pairs (equals 24 terminals) per junction box. Mounted on the outside wall of the shelter (shielded by pair).

- Ethernet switch for serial communication, installed in the local power distribution panel. Plus one (1) local signal junction box, mounted on the outside wall of the shelter.

- Ethernet switch for serial communication, installed in the local power distribution panel. Plus two (2) local signal junction boxes, mounted on the outside wall of the shelter.

- One (1) combined local signal junction box for analog signals (4 - 20 mA, max. load 500 Ohm) and alarms (potential free contacts, max. 24 V DC). Max. 24 pairs (equals 48 terminals). Mounted on the outside wall of the shelter (shielded by pair).

- Two (2) local signal junction boxes. One box for analog signals (4 - 20 mA, max. load 500 Ohm). One box for alarms (potential free contacts, max. 24 V DC). Max. 12 pairs (equals 24 terminals) per junction box. Mounted on the outside wall of the shelter (shielded by pair).

- Ethernet switch for serial communication, installed in the local power distribution panel. Plus one (1) local signal junction box, mounted on the outside wall of the shelter.

- Ethernet switch for serial communication, installed in the local power distribution panel. Plus two (2) local signal junction boxes, mounted on the outside wall of the shelter.

Ventilation:

Optional:

- Natural ventilation: by means of two ventilation openings installed near diagonal corners on opposite walls at floor and top level.

- Forced ventilation: from outside to inside with a single electrical motor driven fan, which is sized to supply a minimum volume equivalent to six air changes per hour. Both the fan (ventilation inlet) and the ventilation outlet are installed near diagonal corners on opposite walls at floor and top level.

- Purge ventilation: applicable for corrosive environments. Instead of outside air a purge of instrument air (IA) is used. The purge is distributed by a collector with individual adjustable silencers. With this option there is always a slight overpressure inside the shelter.

- Natural ventilation: by means of two ventilation openings installed near diagonal corners on opposite walls at floor and top level.

- Forced ventilation: from outside to inside with a single electrical motor driven fan, which is sized to supply a minimum volume equivalent to six air changes per hour. Both the fan (ventilation inlet) and the ventilation outlet are installed near diagonal corners on opposite walls at floor and top level.

- Purge ventilation: applicable for corrosive environments. Instead of outside air a purge of instrument air (IA) is used. The purge is distributed by a collector with individual adjustable silencers. With this option there is always a slight overpressure inside the shelter.

Βαθµός προστασίας:

Depending on configurations

Βάρος :

Approx. 1100 kg (depending on configuration)

Διαστάσεις:

(H x W x D) 2.56 m x 2 m x 2 m

Επιλογές :

Complementary equipment:

- Additional lightning protection by aluminium ringline on the roof conform CE regulation mandatory for outside installation

- Additional electrical sockets 230 VAC / 6A (max. 2)

- Sink with drinking water for cleaning hands or equipment

- Hot water boiler

- Oil free compressor

- Insulation: 4 cm (1.57 ''), K = 0.75 W/m²K)

- Additional lightning protection by aluminium ringline on the roof conform CE regulation mandatory for outside installation

- Additional electrical sockets 230 VAC / 6A (max. 2)

- Sink with drinking water for cleaning hands or equipment

- Hot water boiler

- Oil free compressor

- Insulation: 4 cm (1.57 ''), K = 0.75 W/m²K)

Μοντέλο :

AS4100

Πιστοποιήσεις :

CE Declaration of Conformity conform Machine Directive 2006/42/EC und EMC Directive 2014/30/EU

Τι περιέχει το καλάθι:

AnaShell analytical shelter type AS4100 in ordered configuration; process instrumentation and sample preconditioning pre-assembled and mounted ex works according to order

τροφοδοσία :

Each analyser is powered by a black colored service switch with lock position (suitable for LOTO Lock Out Tag Out) and has an individual circuit braker in the local power distribution panel. An electrical power socket is not needed.

According to CE regulations a local main electrical power switch is mandatory. Options (always with lock position, suitable for LOTO Lock Out Tag Out):

- One (1) local main electrical power switch, single phase 230 VAC / 50 Hz - UPS or non-UPS

- Two (2) local main electrical power switches, single phase 230 VAC / 50 Hz - UPS and non-UPS

- One (1) local main electrical power switch, triple phase 3x380 VAC+N / 50 Hz - UPS or non-UPS

- Two (2) local main electrical power switches, triple phase 3x 380 VAC+N / 50 Hz - UPS and non-UPS

- One (1) local main electrical power switch, single phase 230 VAC / 50 Hz - UPS or non-UPS, plus one (1) local main electrical power switch, triple phase 3x380 VAC+N / 50 Hz - UPS or non-UPS

According to CE regulations a local main electrical power switch is mandatory. Options (always with lock position, suitable for LOTO Lock Out Tag Out):

- One (1) local main electrical power switch, single phase 230 VAC / 50 Hz - UPS or non-UPS

- Two (2) local main electrical power switches, single phase 230 VAC / 50 Hz - UPS and non-UPS

- One (1) local main electrical power switch, triple phase 3x380 VAC+N / 50 Hz - UPS or non-UPS

- Two (2) local main electrical power switches, triple phase 3x 380 VAC+N / 50 Hz - UPS and non-UPS

- One (1) local main electrical power switch, single phase 230 VAC / 50 Hz - UPS or non-UPS, plus one (1) local main electrical power switch, triple phase 3x380 VAC+N / 50 Hz - UPS or non-UPS

Υλικό :

Shelter material: Sandwich construction made of GRP (glass fiber reinforced polyester) by low pressure Resin Transfer Molding (RTM) using UV resistant gelcoat impregnation process.

Base frame material: SS316L (1.4404), insulated (PU foam), including four SS316L (1.4404) lifting and transport brackets, twistable by 90° mounted to the base frame.

Insulation: 2 cm (0.79'') thickness, K = 1.2 W/m²K

Base frame material: SS316L (1.4404), insulated (PU foam), including four SS316L (1.4404) lifting and transport brackets, twistable by 90° mounted to the base frame.

Insulation: 2 cm (0.79'') thickness, K = 1.2 W/m²K